Angle joints, axial joints

Joints in the KIPP range

Joints play a key role in numerous technical applications. These operating parts are used for the mechanical connection of moving parts and allow for precise control of movements and forces. Joints are available in a variety of styles and sizes to meet specific requirements of different industries. Whether in robotics, manufacturing or medical technology, the reliability and precision of joints is crucial to the efficiency of the entire system.

One of the main functions of joints is to enable movement while ensuring stability. Joints are able to withstand high loads and as a result operate with low friction and wear resistance. This requires the use of high-quality materials and sophisticated designs.

Angle and axial joints are, as the name suggests, also part of the this product family. The two types of joint play a critical role in the industry as well as in various sectors by allowing for specific movements and power transmission.Angle joints are mechanical connections. They transmit rotary movements between two shafts that are at a certain angle to each other. Angle joints are particularly useful in conditions where a rigid connection is not possible or advantageous. The manufacturing industry is a common area of application for angle joints. There, they are used in machines and tools to transmit movements via complex paths. Angle joints are also used in robotics, as they increase mobility and flexibility of robot arms and consequently enable complex tasks.Axial joints, on the other hand, are designed to convert axial movement and transmit forces in a straight line. They are widely used in the automotive industry, especially in steering and suspension systems. Axial joints help to improve vehicle steering and stability by supporting the movements of the steering rods and suspension elements.

The importance and use of angle and axial joints extends across many industrial applications and sectors. Their ability to transmit movement and force effectively makes them essential components in the operation of modern systems. Their development and adaptation to specific technical requirements contributes significantly to efficiency, precision and safety in industry.

What are angle joints?

What are axial joints?

Angle und axial joints by KIPP

Criteria when selecting joints

KIPP as manufacturer of axial and angle joints

What are angle joints?

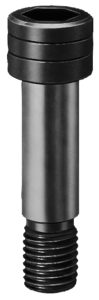

In technical systems angle joints perform the important task of transmitting rotary movements between two shafts that are at a certain angle to each other. This capability makes them particularly valuable in circumstances where rigid connections are impractical due to the geometric arrangement or the need for flexibility of movement. Angle joints are made up of a ball joint and a housing. The interaction between ball joint and housing allows for a flexible connection. In order to ensure optimum performance and durability, the specific design and materials used are determined by the DIN standard.

Angle joints are widely used in industry as they allow for transmission of movements and forces in machines and tools that are not positioned linearly. Due to their ability to route movements along complex paths, they increase flexibility and efficiency of technical systems. Angle joints are typically made up of several components that are designed so that they can transmit rotary movements with minimum play and maximum precision.

A central function of angle joints is the compensation of angle deviations between connected shafts. They enable continuous and constant power transmission, even if the shafts move at different angles to each other. This is crucial in many industrial applications to ensure efficiency and service life of machines. Angle joints are designed to withstand high mechanical loads while offering high precision and minimising friction losses at the same time.

Angle joints are essential in numerous industrial and technical applications due to their ability to transmit rotary movements at different angles. Their design and operating principle contributes significantly to performance, flexibility and reliability of modern machines and systems.

Angle joints in the KIPP product range

The KIPP-product range includes angle joints in two styles.

The angle joint is manufactured according to DIN 71802. The DIN 71802 standard ensures that angle joints fulfil the high requirements of various industrial applications. It defines dimensions and tolerances, materials and mechanical properties in order to guarantee reliability and efficiency of the joints. This facilitates selection and integration of angle joints in technical systems and contributes to standardisation and quality control in the industry.

For angle joints according to DIN 71802 material can be selected. You are able to choose between steel and stainless steel 1.4305.

Our material overview will help you determine which of the two materials is better suited for your application. There we have listed and clearly outlined individual properties of the materials.

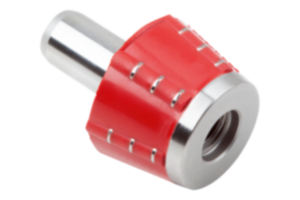

The second angle joint, K0734, is made of stainless steel and features a neoprene sealing cap. The operating part is similar to DIN 71802 and is specifically designed for use in difficult environmental conditions such as dust and lubricants. The sealing cap covers and seals the gap between spherical seat and ball stud.

What are axial joints?

An axial joint transmits movements in a specifically controlled manner. It allows for rotating or swivelling movements around an axis and is often used in machines and devices where precise control of movements is needed.

Axial joints are essential in industrial and technical applications as they offer flexibility and manoeuvrability without compromising stability and accuracy. A typical example is the use in operating levers that enable precise control of machines and vehicles. Here, the axial joint allows for movement to be carried out in different directions while maintaining feedback and control over the motion sequences.

Axial joints in operating parts are often sturdily designed to withstand the stresses of daily use. They are available in a variety of materials and styles to meet specific requirements of different applications. Choosing the right axial joint depends on factors such as the required freedom of movement, load rating and environmental conditions in which the operating part is used.

As a manufacturer, we have two axial joints in our product range.

- Axial joint similar to DIN 71802

- Adjustable axial joints for tractive forces

Thanks to our many years of experience as a manufacturer, we are frequently asked the same questions about axial joints. We would like to answer them as follows.

How do you know when an axial joint is worn out?

If an axial joint is worn out, you may encounter the following indicators:

- Play or gaps: A clear sign of a worn axial joint is a noticeable play or looseness in movement. This can result in the operating part appearing loose or imprecise and having an undesirable free play that exceeds normal levels.

- Irregular movements: A worn axial joint can lead to irregular movements, especially if the joint loses is out of its original alignment or moves during operation. This can cause the operating part to react unpredictably or be more difficult to control.

- Crackling or rattling: If the axial joint is badly worn, this can lead to noises such as crackling or rattling, especially during movement. These noises indicate that the joint is no longer fixed and moving during operation.

- Sluggishness: A worn axial joint can also cause the operating parts to become sluggish or harder to move than usual. This may indicate that the joint is experiencing friction or resistance when it moves, due to wear and tear or deformation of the joint mechanisms.

- Loss of control: Finally, a worn axial joint can lead to loss of precision during a movement. This can be particularly problematic if the operating part is used to control machines or vehicles, as unwanted movements can lead to safety risks.

However, it should also be emphasised that detecting a worn axial joint is quite difficult! The defect is often only recognised during maintenance. Repair or replacement of the joint is required to restore proper function of the axial joint!

How long does an axial joint last?

That is a difficult to answer. The service life of an axial joint can vary greatly and depends on different factors. The following key aspects influence the service life of an axial joint:

- Material quality

- Operating conditions

- Load and frequency of use

- Maintenance and care

Therefore: An axial joint that is subjected to heavy loads on a daily basis will not last as long as one that is only used occasionally. There is no general time period for how long an axial joint will last.

The KIPP product range at a glance

In addition to axial and angle joints, the KIPP range also includes other operating parts in this category. The individual parts are briefly described below.

R-clips are locking elements that are often used to secure bolts, axles or pins against unintentional removal. They are made of a elastic material that ensures secure locking when inserted into a hole or groove. R-clips are easy to install and remove. The KIPP R-clips are manufactured similarly to DIN 11024 and are either made of steel or A2 stainless steel.

Clevis fastener are mechanical connections that join two components together and allow limited movement in different directions. They are made up of a fork-like structure that engages in a corresponding counter-component and often secured with a bolt. Fork joints are used in the automotive and mechanical engineering industry to create flexible connections that can compensate for slight angular deviations.

Rod-end eye are connecting elements with ball bearings. Operating parts by Kipp are available in steel or stainless steel 1.4305. They enable movement around several axes, providing a stable and robust connection at the same time.

Linch pins are fastening elements that allow a quick and secure connection between two components. They are made up of a pin with a hinged lock that is folded down after insertion into a hole to prevent it from slipping out.

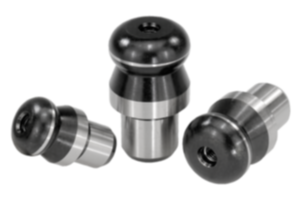

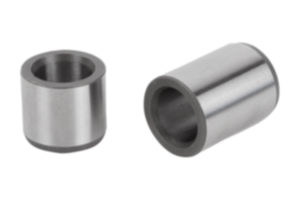

Ball cups are mounting units running on ball bearings that create a rotating connection to a ball or ball stud. They allow low-friction movement in all directions and are used in conjunction with ball studs. Ball cups are used in steering systems, suspension systems and mechanical control systems where flexible and precise movement is needed.

Ball studs are spherical end pieces that are used as slewing rings and swivel joints in combination with ball studs. They offer low-friction, multidirectional movement and are often used in automotive engineering, agricultural machinery and various industrial applications. Ball studs are crucial for applications that require high manoeuvrability and load capacity.

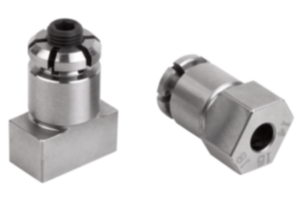

Quick-fit couplings are connecting elements that allow quick and easy connection and disconnection of hoses or pipe lines. They typically consist of two parts: a coupling and a plug-in nipple. By simply plugging them together, the parts snap into place and ensure a tight connection. Quick-release couplings are often used in hydraulic, pneumatic and fluid systems where quick maintenance or replacement of components is needed.

Circlips are used to secure components against unintentional loosening or slipping. They are made of spring steel and have a U-shape that is placed over bolts or pins to secure them.

A cotter pin is a thin metal pin that is inserted into a hole or through a hole in a bolt or axle. The cotter pin is then bent over to prevent it from slipping out.

Criteria when selecting joints

Selecting the right joint for a particular application requires several criteria to be taken into account. The most important one being: Know your exact requirements! Be it load capacity, ambient conditions or choice of material.

- It is important to know what loads the joint has to bear, both at rest (static) and in motion (dynamic). Joints must be designed for the maximum expected load.

- Also determine whether the joint is mainly exposed to tensile, compressive or shear forces.

- Ensure that the joint uses materials and lubricants that can withstand expected temperature ranges.

- Select joints made of materials that are resistant to moisture and corrosive environments, especially in marine or chemical applications.

- Also consider the need for seals or protective covers to prevent the ingress of dust and dirt.

- Depending on the application materials such as hardened steel, stainless steel or special alloys may be required. In applications where weight is an issue, lighter materials such as aluminium or titanium may be preferred.

By carefully considering these criteria, you can ensure that the selected joint meets the requirements of your particular application and offers reliable and long-lasting performance.

KIPP as manufacturer of axial and angle joints

KIPP offers a comprehensive range of high-quality axial and angle joints that have been specifically developed to meet the requirements of a wide variety of applications. Our angle joints are particularly versatile and available with right-hand and left-hand threads, which allows for flexible transmission and redirection of forces. This feature makes them perfect for complex mechanical systems where precise control and reliability are crucial.

Another purchasing advantage is that customers can order any quantity of KIPP products they require. We are well aware that individual requirements in regard to joints can vary, so we offer sales units fitting your needs. The more parts you buy, the lower the unit price will be. This is a cost-effective solution, regardless of the size of your project.

In addition, the products in the category are combinable, which provides you with additional flexibility when designing your systems. For example, our clevis fasteners fit a wide range of rod ends perfectly, facilitating integration into existing systems and allowing you to create customized solutions that match your requirements perfectly.