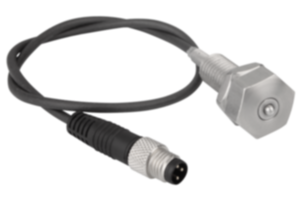

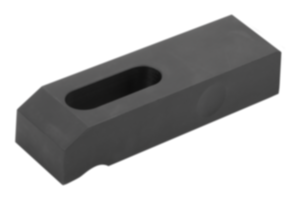

Contact sensor stainless steel.

Plug housing steel.

Description

Contact sensor stainless steel.

Plug housing steel.

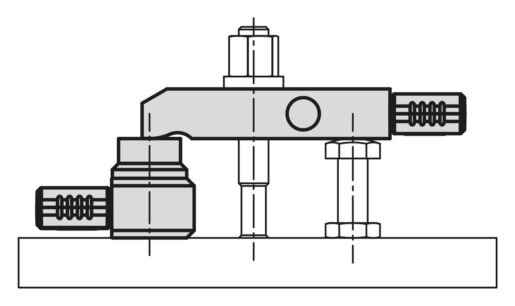

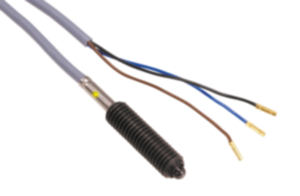

A limit switch, which is integrated into the rest pad with contact sensor, detects whether a workpiece is supported or not. The pressure of a workpiece on the sensor closes a contact, causing the sensor to detect it.

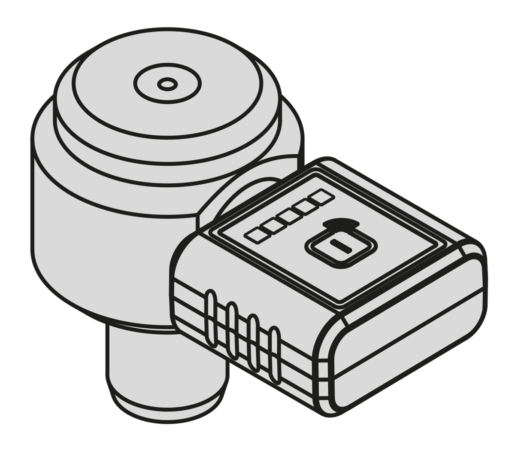

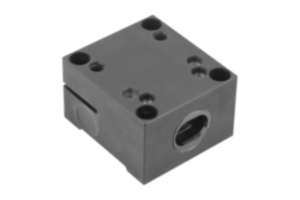

If the rest pad is equipped with an universal transmitter, the status of the sensor can be recorded and processed electronically.

The power supply for the rest pad is provided by the universal transmitter, which can be replaced if necessary without reconfiguration.

The Universal transmitter K1831 can be connected to the rest pad via USB Type-C.

A secure signal transmission can only be guaranteed if the contact sensor is pressed down by the workpiece flush with the contact surface.

The contact surface of the workpiece must be larger than Ø10 mm.

Tolerance 0.2 mm.

2) USB type C

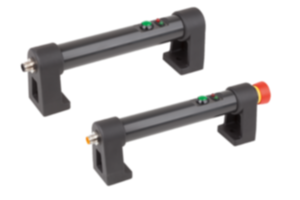

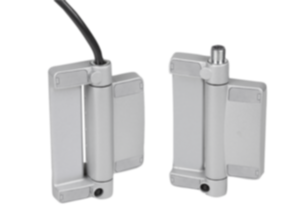

Gateway K1494.

Smart Products by KIPP

In an increasingly networked Industry 4.0 environment, our smart products support the efficient organisation and monitoring of manufacturing processes.

Smart products from KIPP offer an ideal solution for the error-free machining of workpieces, e.g. in the field of machining. They make it easy to check fixtures and stops before machining. KIPP offers various intelligent components for these and other areas of application.

Our innovative components ensure precise machining and increased repeat accuracy - from intelligent support bolts to clamps with force sensors.

Our Bluetooth modules enable convenient data transfer and visualisation, while the gateway as an interface between the smart product and machine control ensures precise processes.

Whether on a tablet, smartphone or desktop - with our user-friendly web application, you retain control of your clamping systems. Simultaneous monitoring of several tools in different machining centres and production systems is also possible with this application.