Rubber buffers

Rubber buffers are intended to be used as a flexible buffer element and to reduce vibrations.

Rubber buffers from KIPP

Rubber buffers are used to dampen shocks, vibrations and oscillations and are sometimes called impact buffers. Most of the elastic vibration dampers are made of rubber, but the material for the body can vary. Typical materials used for the body are steel or stainless steel.

Rubber buffers are used as protective and damping elements in various mechanical applications. They act as a sort of ‘buffer zone’ between two hard surfaces.

The mechanical energy generated by shocks, movements or vibrations is absorbed and distributed by a rubber buffer. They absorb undesirable movements and minimise the transmission of forces or vibrations to other parts. These vibration dampers thus prevent this energy from being transferred unhindered to other components.

Rubber buffers protect sensitive components from damage, wear and tear and prevent unwanted noise. This increases the service life of machines and appliances and reduces noise. There are many different types of rubber buffers available to meet different requirements. This diversity means that the buffers are used in many different areas.

Anti-vibration mounts are used in machines and industrial plants at connection points, bearings or as feet. They dampen vibrations caused by rotating parts and reduce noise. Vibration dampers also protect sensitive components from damage caused by mechanical shocks. In vehicles, rubber buffers are used in the suspension and engine mounts, as well as in car bumpers and door hinges.

Regardless of the application, rubber buffers are an inexpensive and effective way of reducing mechanical loads. Invest in the longevity of your systems now!

Advantages of KIPP rubber buffers

Individual rubber buffers at a glance

KIPP as your reliable manufacturer of rubber buffers

Advantages of KIPP rubber buffers

The rubber buffers from KIPP are specially designed for a wide range of applications. Their high-quality rubber compounds and flexible application options make them a reliable solution for absorbing oscillations and vibrations. However, these vibration dampers also have other advantages.

- Reduced maintenance costs through high-quality materials: Rubber buffers, such as those from KIPP, are made from special natural rubber compounds. This offers a long service life and resistance to wear and tear. As the components need to be replaced or serviced less frequently, it helps to significantly reduce maintenance costs.

Further information on the material can be found in our material overview under natural rubber.

- Durability and resilience: Due to the use of high-quality materials, the rubber bumpers are particularly durable and resistant. They can also be used in demanding environments, which extends their range of applications.

- Simple installation: Vibration dampers are easy to install, which saves time and costs during assembly. They do not require any special tools or complex procedures, making them a practical solution for many applications.

- Effective damping of vibrations and impacts: The rubber buffers from KIPP offer excellent damping properties that effectively absorb vibrations and impacts. This prevents any undesirable fluctuations from spreading to the entire system. Which in turn improves the performance and safety of the machines.

- Noise reduction: Rubber buffers reduce noise emissions by absorbing vibrations and impacts. This helps to improve the working environment in many applications.

- Diverse application possibilities: Rubber buffers are available in a variety of designs, making them suitable for a wide range of applications in various industries. Their flexibility enables them to be used in a wide range of temperatures, from -30 to +80 °C. As a result, the impact buffers function perfectly, even under varying environmental conditions.

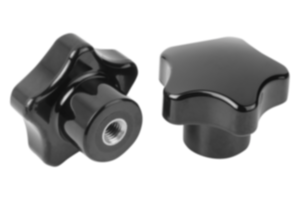

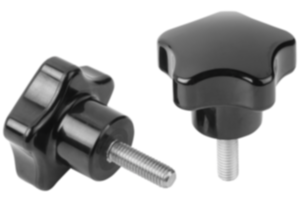

Individual rubber buffers at a glance

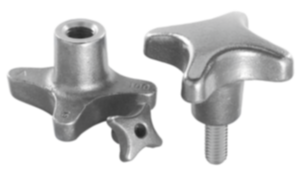

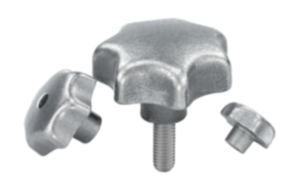

KIPP is well represented with 21 different products. In addition to the design, these can also be distinguished by the body material. The bodies of the rubber buffers are made from stainless steel or steel. These materials are suitable for use in demanding environments where high load capacity and resistance are required.

Our buffers combine the best properties of the materials used to ensure effective damping and protection.

Stainless steel is characterised by its excellent corrosion resistance, high strength and durability. Stainless steel is also resistant to rust and chemicals. Stainless steel bodies are particularly suitable for applications subject to high hygiene requirements or in corrosive environments.

A steel body offers high strength and resistance to mechanical loads. Steel is a cost-effective material that is widely used in many industrial applications.

It gives the vibration damper a high level of stability. The material is suitable for use in heavy machinery and systems that are exposed to high mechanical loads. It is ideal for industrial applications where high forces need to be absorbed.

For all products, the rubber impact buffer part is made from a natural rubber elastomer. Natural rubber (NR) is an elastic material that is characterised by its excellent damping and high restoring properties. It is particularly effective at absorbing vibrations and impacts and remains flexible even at low temperatures.

The material offers an excellent balance between flexibility and hardness. This makes the rubber buffers ideal for applications where both good damping and high load-bearing capacity are required.The combination of a stainless steel or steel body with a natural rubber elastomer damping element offers excellent performance in various applications.

Particularly popular products in our range:

- Cylindrical rubber buffers type A, with external threads both sides

- Cylindrical rubber buffers type B with internal thread and external thread

- Cylindrical rubber buffers type D with one external thread

KIPP as your reliable manufacturer of rubber buffers

KIPP is a German company specialising in the development, manufacture and sale of clamping, standard and operating parts. Since our foundation, the company has developed into a renowned supplier in the machine construction and automation industry. We are renowned for our high-quality products, which find use in many industrial sectors worldwide.

We continuously invest in research and development. This enables us to offer new solutions for the challenges to industry and to improve and expand our product range. All our products are manufactured in Germany to the highest quality standards. This is confirmed by our ISO 9001 certification.