Material

Clamping rail and fixed jaw tool steel.

Wedge clamp mild steel.

Wedge clamp mild steel.

Version

Clamping rail and fixed jaw hardened and ground (HRC 55 ±2).

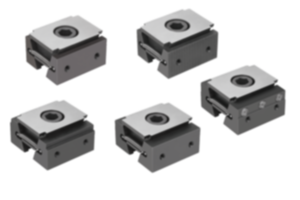

Wedge clamp hardened, phosphated.

Wedge clamp hardened, phosphated.

Show more

Show less

Description

Material

Clamping rail and fixed jaw tool steel.

Wedge clamp mild steel.

Wedge clamp mild steel.

Version

Clamping rail and fixed jaw hardened and ground (HRC 55 ±2).

Wedge clamp hardened, phosphated.

Wedge clamp hardened, phosphated.

Note

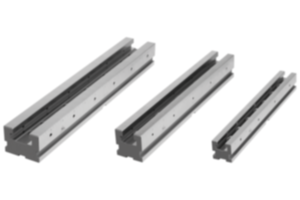

The multi-clamping system can be fastened using various interfaces.

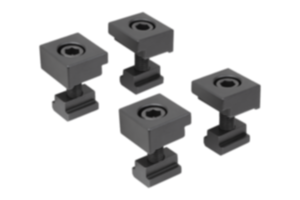

1. Lateral clamping edge for clamping claw set. Claw clamps can be fastened at any position.

2. Holes for DIN cap screws.

3. Ø25 mm locating holes for conventional zero-point clamping systems with 200 mm spacing.

4. Ø16 mm locating holes for zero-point clamping systems with 96 mm spacing.

5. Three 18H7 alignment slots for crosswise and lengthwise alignment on T- slot tables.

6. Ø12F7 and Ø16F7 reamed holes for 40 and 50 mm grid systems.

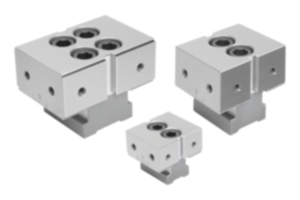

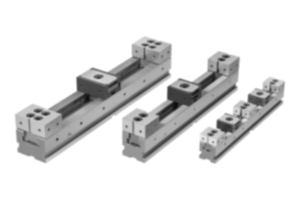

Three different versions are available:

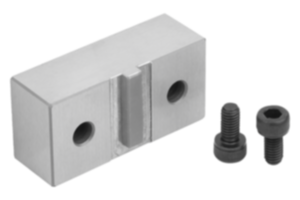

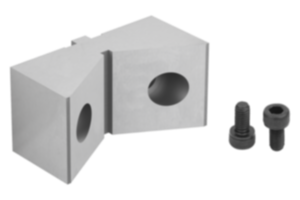

- Multi-clamping system double-sided wedge clamp with OS fixed jaw / K1828.

- Multi-clamping system double-sided wedge clamp with DS fixed jaw / K1829.

- Multi-clamping system single-sided wedge clamp with OS fixed jaw / K1830.

1. Lateral clamping edge for clamping claw set. Claw clamps can be fastened at any position.

2. Holes for DIN cap screws.

3. Ø25 mm locating holes for conventional zero-point clamping systems with 200 mm spacing.

4. Ø16 mm locating holes for zero-point clamping systems with 96 mm spacing.

5. Three 18H7 alignment slots for crosswise and lengthwise alignment on T- slot tables.

6. Ø12F7 and Ø16F7 reamed holes for 40 and 50 mm grid systems.

Three different versions are available:

- Multi-clamping system double-sided wedge clamp with OS fixed jaw / K1828.

- Multi-clamping system double-sided wedge clamp with DS fixed jaw / K1829.

- Multi-clamping system single-sided wedge clamp with OS fixed jaw / K1830.

Technical Data

System width 50

Maximum clamping force: 10 kN

Maximum tightening torque: 30 Nm

System width 72

Maximum clamping force: 20 kN

Maximum tightening torque: 50 Nm

System width 100

Maximum clamping force: 30 kN

Maximum tightening torque: 65 Nm

Maximum clamping force: 10 kN

Maximum tightening torque: 30 Nm

System width 72

Maximum clamping force: 20 kN

Maximum tightening torque: 50 Nm

System width 100

Maximum clamping force: 30 kN

Maximum tightening torque: 65 Nm

Application

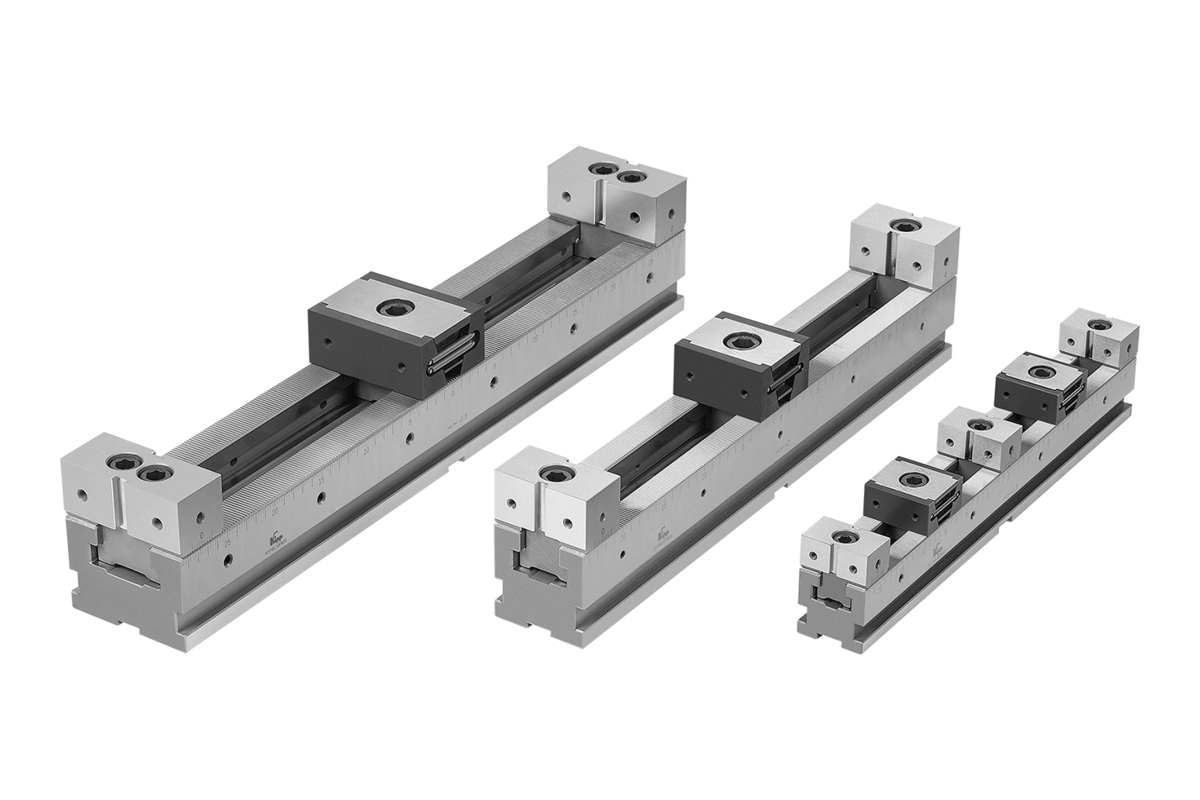

A number of multi-clamping systems with different lengths can be mounted one behind the other or beside each other. The precision toothing enables highly precise positioning of the fixed jaws. Due to the lateral graduations on the clamping rails, each position of the fixed jaws can be documented and reset identically. Stops can be mounted in the tapped holes on the side.

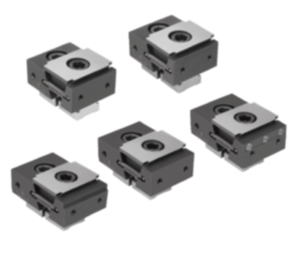

Turning the clamping screw moves the clamping segments outwards and press the workpieces against the fixed jaw.

Turning the clamping screw moves the clamping segments outwards and press the workpieces against the fixed jaw.

Advantages

Universal and flexible.

For small and large batch sizes.

Large components can also be clamped next to each other on several multiple clamping systems.

For small and large batch sizes.

Large components can also be clamped next to each other on several multiple clamping systems.

Scope of delivery

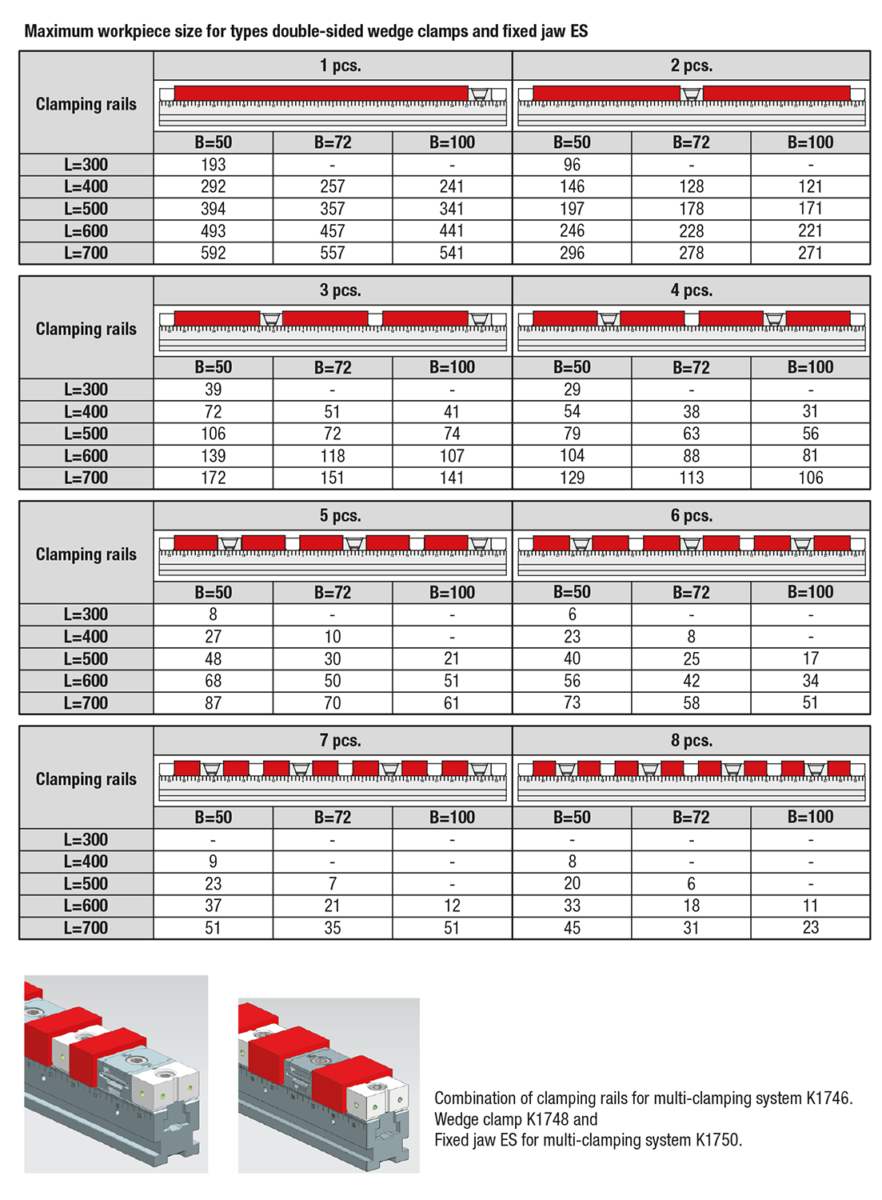

1x clamping rail

The number of wedge clamps and fixed jaws is dependent on the system size (see table).

The number of wedge clamps and fixed jaws is dependent on the system size (see table).

Accessory

Clamping pin K0967.

Cap screws K0869.

Shoulder screws K0815.12045 / K0815.16055.

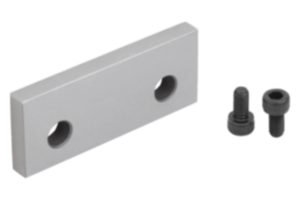

Seating ledges K1752.

Attachment jaws with machining allowance K1753.

Attachment jaws with prism K1754.

Workpiece stop K1755.

Spacer K1756.

Clamping claw set K1757.

T-slot nut K1758.

T-slot key K0954.

Cap screws K0869.

Shoulder screws K0815.12045 / K0815.16055.

Seating ledges K1752.

Attachment jaws with machining allowance K1753.

Attachment jaws with prism K1754.

Workpiece stop K1755.

Spacer K1756.

Clamping claw set K1757.

T-slot nut K1758.

T-slot key K0954.

Important note on downloading CAD models

You must log in before you can download our CAD models. If you have not yet created an account, please register under "My account" (right-hand side of the screen) and follow the instructions.